It all started with a problem:

How best to address the energy wasted by billions of recessed lighting fixtures throughout the world?

There are over 600 million non-IC can lights in the US alone that require special treatment. These lights are the single biggest energy waster in the home insulation envelope. The challenge is balancing efficiency with safety. Just adding insulation without proper treatment defeats the purpose of insulating.

Our research revealed that no existing solution addressed both efficiency and safety without compromising on one or both. Common knowledge held that Non-IC lights could not be covered. We did not accept this. Thus we set out to develop CanCoverIt.Finding a solution became a journey of discovery in applied geometry culminating in development of CanCoverIt, the perfect solution for retrofits and new installs, Non-IC and IC fixtures.

Soon after fielding for Non-IC we began to have customers seek us out to solve their IC can-light problems, from continued energy waste to water dripping from fixtures. It turns out that air-sealing was not the whole story, and was even causing more problems around moisture and mold buildup.

Today CanCoverIt is recognized as the only true solution for all can-lights, bathroom fans, exchange fans, speakers, and other metal attic penetrations!

Before CanCoverIt

Existing Solution Landscape Full of Compromise

Original Non-IC Can Light (Downlight)

Safety: Pass | Performance: Fail

Most common fixture type with more than 500 million in use

Heat entrapment prevention requires no Insulation contact

Early versions have no thermal shut off mechanisms

Later models may have thermal shut off set for high heat

Metal fixture is highly conductive and can attract condensation

Designed to draw air through fixture to prevent overheating

Critical energy waster - severely compromises insulation envelope

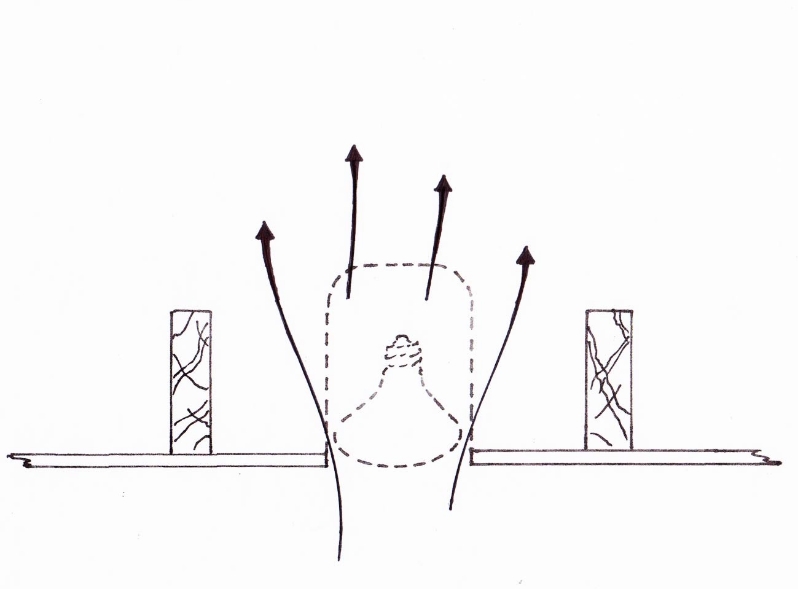

Non-IC Width Open Barrier Insulating Treatment

Safety: Pass | Performance: Fail

Efforts to improve energy efficiency added insulation thickness above fixture

Safety code evolved to read: “no insulation above in a manner to entrap heat”

Chimney effect phenomenon can draw more air through than untreated fixture

Metal fixture remains highly conductive and can attract condensation

Open attic space creates hot and cold spots and drafts in the ceiling

Critical energy waster - severely compromises insulation envelope

Barrier use can negate overall R-Valve benefit of added insulation thickness

Non-IC Open Barrier Treatment with Air-seal Insert

Safety: Fail | Performance: Fail

Can effectively stop air flow through the fixture, but not around fixture

Potential overheating hazard in hot ambient temperature attic conditions

Metal fixture remains highly conductive and can attract condensation

Open attic space creates conductive hot and cold spots in the ceiling

Can entrap heat and shorten the lifespan of CFL and LED light bulbs

Not compatible with original Non-IC airflow intent to prevent heat entrapment

Does not address conductive energy loss and compromises insulation envelope

Non-IC Low Flat-top Box Treatment with Vents

Safety: Fail | Performance: Fail

Flat top box terminates within insulating layer to improve R-Value

Weak structure can sag or even collapse under the weight of insulation

Limited size provides insufficient air volume above and/or around fixture

Incandescent bulb generates heat at a faster rate than it can dissipate

Insulation blocked openings provide slow air venting and entrap heat

Addresses conductive heat transfer, but is moisture and airflow permeable

Concentrates high heat around fixture and sensitive electrical components

Non-IC Flat Box with Open Vent Channel

Safety: Fail | Performance: Fail

Flat top box terminates within insulating layer to improve R-Value

Provides insufficient air volume above and/or around fixture

Flat horizontal top creates dam effect that impedes airflow and entraps heat

Weak structure can sag or even collapse under the weight of insulation

Concentrates high heat around fixture and sensitive electrical components

Incandescent bulb generates heat at a faster rate than it can dissipate

Addresses conductive heat transfer, but is moisture and airflow permeable

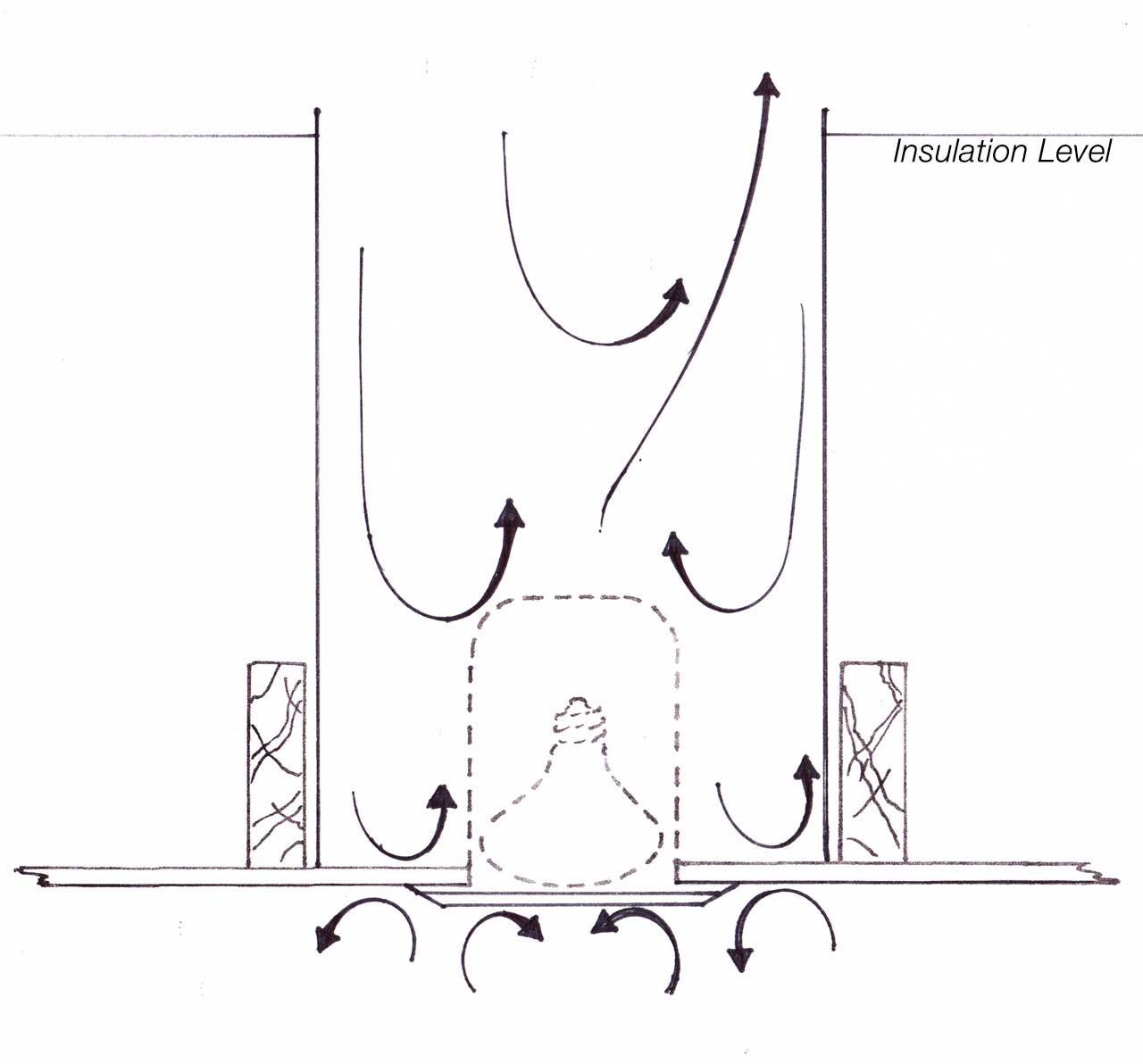

Non-IC Tall Box Treatment

Safety: Fail | Performance: Fail

Flat top box (typically drywall) terminating above insulation layer (envelope)

Size provides more air volume to dissipate heat, but compromises insulation

Addresses airflow (convection), but not conduction and moisture conditions

Non insulated top transfers energy and compromises overall home insulation (R-Value)

Conduction alone may not dissipate heat at a fast enough rate to prevent overheating

High heat concentrations within box may damage sensitive electrical components

Closed box can entrap heat, with peak hazard occurring during hot attic conditions

Non-IC Tent Design Treatment

Safety: Fail | Performance: Fail

Tent style sides can sag or even collapse under the weight of insulation

Angled sides allow hot air to rise with less restriction than a flat top box

Angled sides allow top area to be better insulated than a tall box

However, the shape does limit top insulation thickness along panel width

Shape limits compartment size and air volume in critical area around fixture

Size to air volume ratio above and/or around fixture is not optimum

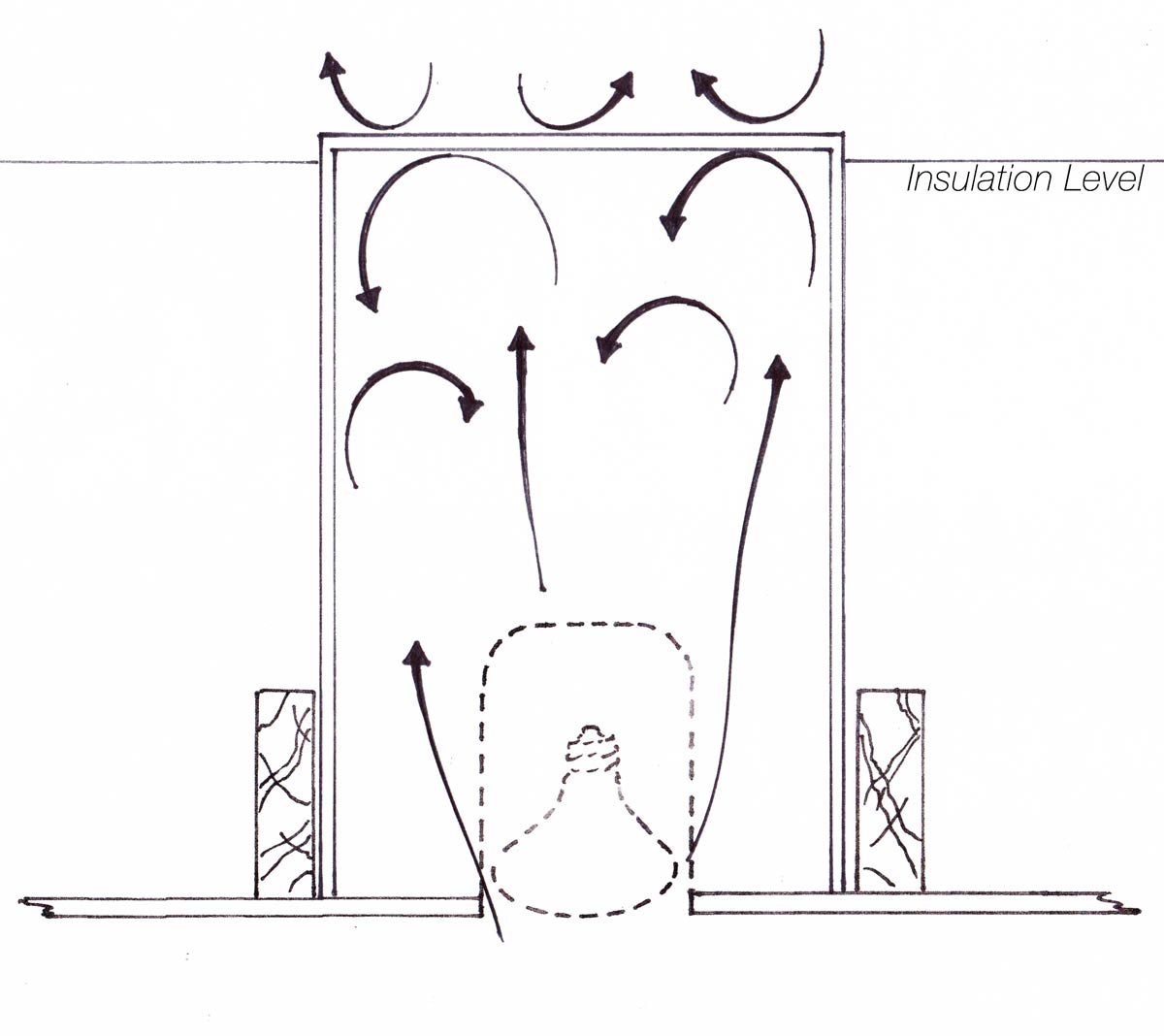

Enter CanCoverIt Universal Series

The Ultimate Solution

Safety: Pass | Performance: Pass

Stable base optimizes air space safety and makes installation a breeze

Converging top panels provide thermal performance and strength

Turning the light on activates the safety mode to prevent overheating

Materials are non-conductive fire and mold resistant, air and watertight

Secondary covers protect the vents even when blowing in insulation

Innovative design provides a lifetime of fail-safe energy efficiency

"I had been using Insullite, but constructing the box in the cramped attic is a bit tedious, not to mention trying to tape the seams. After trying CanCoverIt once, I am sold. I have already told my distributor that they better start carrying CanCoverIt if they want my business."

- Kenny, contractor, Colorado Springs, CO

"What do you like most about CanCoverIt?" 2:04

"What about other solutions like IC can-lights?" 3:31

"Install myself or hire a pro?" 4:12

"Advice for homeowners?" 5:21

"How does CanCoverIt fit into my budget?" 6:23